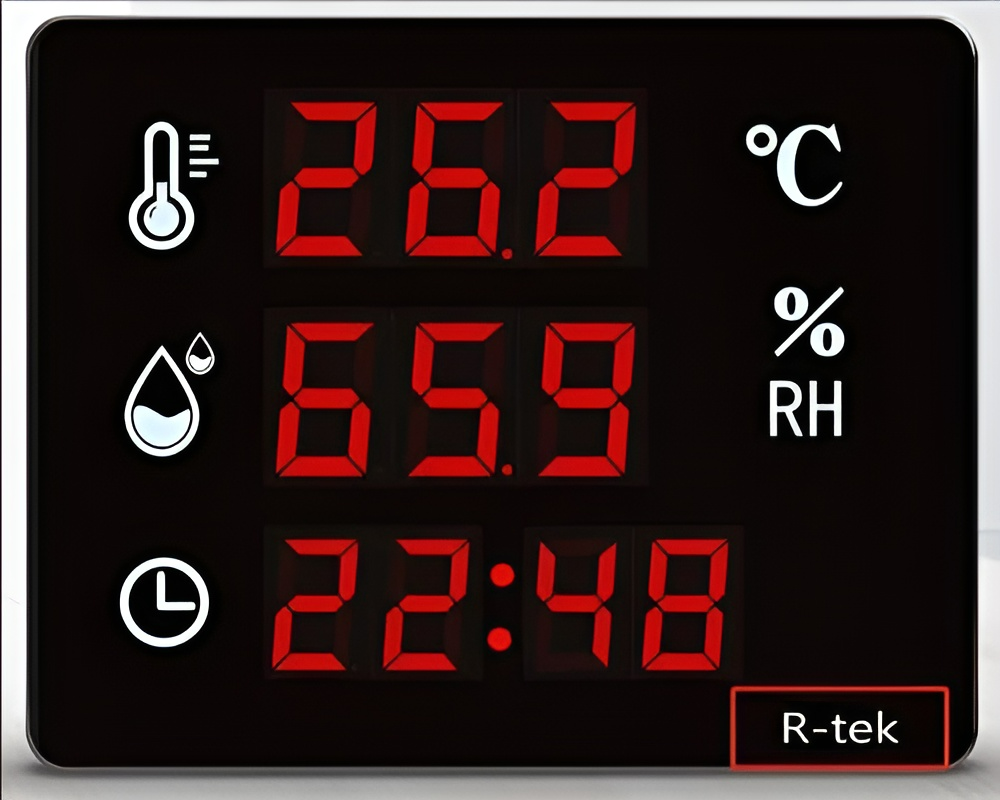

ACTUAL PICTURES of factory temperature and humidity meter

What is a factory temperature and humidity meter?

A factory temperature and humidity meter, also known as an industrial temperature and humidity meter, is a device used to measure and monitor the temperature and humidity levels in a factory or industrial environment. It is designed to provide accurate and real-time measurements for maintaining optimal conditions and ensuring the quality and safety of products and processes.

What are the benefits of factory temperature and humidity meters?

Quality control

Temperature and humidity are critical factors in many manufacturing processes. By accurately monitoring and controlling these parameters, factories can ensure consistent product quality and reduce the risk of defects. The meters help identify deviations from the desired conditions, allowing prompt corrective actions.

Energy efficiency

Efficient energy management is crucial in factories. By monitoring temperature and humidity, facilities can optimize heating, ventilation, and air conditioning (HVAC) systems to operate at the most energy-efficient levels. Proper control of these parameters can lead to significant energy savings and reduced operational costs.

Equipment protection

Industrial equipment, such as machinery, electronics, and raw materials, can be sensitive to temperature and humidity variations. High or low temperatures, excessive moisture, or dry conditions can damage equipment, degrade performance, and shorten their lifespan. Temperature and humidity meters help maintain optimal conditions, protecting valuable assets and reducing maintenance costs.

Regulatory compliance

Many industries have specific regulations and standards regarding temperature and humidity control. Factory temperature and humidity meters help ensure compliance with these requirements, allowing businesses to avoid penalties, maintain certifications, and meet industry guidelines.

Data logging and analysis

Advanced temperature and humidity meters offer data logging capabilities, allowing the collection and storage of temperature and humidity readings over time. This data can be analyzed to identify patterns, trends, and correlations, providing valuable insights for process optimization, troubleshooting, and decision-making.

Factory temperature and humidity meter - Optimal solution

Application of factory temperature and humidity meter

Some of the common applications include:

-

Manufacturing and Production Facilities: Temperature and humidity control is critical in industries such as pharmaceuticals, food processing, electronics manufacturing, and chemical production. These meters are used to monitor and control environmental conditions to ensure consistent product quality, optimize production processes, and comply with regulatory standards.

-

Warehousing and Storage: Temperature and humidity meters are used in warehouses and storage facilities to monitor the conditions of stored goods. They help prevent spoilage, degradation, and damage to products that may be sensitive to temperature and humidity fluctuations, such as perishable goods, pharmaceuticals, and certain chemicals.

-

Cleanrooms and Laboratories: Cleanrooms and laboratories require precise temperature and humidity control to maintain sterile and controlled environments. These meters are used to monitor and regulate conditions in cleanrooms used in industries like semiconductor manufacturing, biotechnology, and medical device production.

-

HVAC Systems Monitoring: Temperature and humidity meters are used in conjunction with heating, ventilation, and air conditioning (HVAC) systems to monitor and optimize their performance. These meters help ensure energy-efficient operation, maintain comfortable working conditions for employees, and prevent equipment failures caused by extreme environmental conditions.

-

Data Centers: Temperature and humidity control are crucial in data centers to protect sensitive equipment and ensure optimal performance. Factory temperature and humidity meters help monitor and maintain the required conditions for data centers, preventing overheating, condensation, and equipment malfunctions.

-

Agriculture and Horticulture: In agricultural and horticultural settings, temperature and humidity meters are used to monitor and control the growing environment. They help optimize conditions for plant growth, prevent diseases caused by excessive humidity, and ensure the well-being of livestock in controlled farming environments.

Why should you use a factory temperature and humidity meter?

- Product Quality and Consistency: Certain manufacturing processes and products are sensitive to temperature and humidity variations. By using a temperature and humidity meter, you can monitor and control these parameters to ensure consistent product quality. Maintaining optimal conditions helps prevent defects, product spoilage, and variations in performance.Equipment Protection: Industrial equipment, machinery, and materials can be

- negatively affected by extreme temperatures and humidity levels. By using a temperature and humidity meter, you can detect and address conditions that may lead to equipment damage or premature wear. Protecting your equipment helps extend its lifespan, reduce downtime, and avoid costly repairs or replacements.

- Regulatory Compliance: Many industries have specific regulations and standards regarding temperature and humidity control. Utilizing a temperature and humidity meter enables you to monitor and demonstrate compliance with these requirements. It helps you avoid penalties, maintain certifications, and adhere to industry guideline

- Energy Efficiency: Monitoring and optimizing temperature and humidity levels can contribute to energy efficiency in your factory. By using a meter, you can identify inefficiencies, adjust HVAC systems, and implement energy-saving measures. This can lead to reduced energy consumption, lower utility costs, and a smaller environmental footprint.

- Early Warning and Preventive Maintenance: Temperature and humidity meters often include alarm features that alert you when conditions deviate from the desired range. This early warning system allows you to take prompt action to prevent equipment failures, product spoilage, or safety hazards. Additionally, monitoring conditions over time helps you identify trends and plan preventive maintenance to minimize downtime and maximize equipment reliability.

- Process Optimization and Data Analysis: Temperature and humidity data collected by the meter can be analyzed to identify patterns, trends, and correlations. This information can help you optimize processes, troubleshoot issues, and make informed decisions. Analyzing historical data can uncover insights for improving efficiency, reducing waste, and enhancing overall productivity.

Factory temperature and humidity meter

Note when using the factory temperature and humidity meter

-

Calibration: Ensure that the meter is properly calibrated before use. Calibration ensures the accuracy and reliability of the measurements. Follow the manufacturer’s instructions for calibration or have the meter calibrated by a professional if required.

-

Placement: Place the meter in a representative location within the factory environment. Consider factors such as airflow patterns, proximity to heat sources or vents, and potential obstructions that may affect the accuracy of readings. Avoid placing the meter in direct sunlight or in areas with excessive moisture or dust accumulation.

-

Maintenance: Regularly maintain and clean the temperature and humidity meter according to the manufacturer’s recommendations. This may include cleaning the sensors, replacing batteries, and checking for any signs of wear or damage. Proper maintenance helps ensure accurate readings and prolongs the lifespan of the meter.

-

Monitoring Periods: Determine the appropriate monitoring periods based on your specific requirements. Depending on the industry and processes involved, continuous monitoring may be necessary, or periodic measurements at specific intervals may be sufficient. Establish a monitoring schedule that suits your needs and regulatory requirements.

-

Data Recording: Keep a record of temperature and humidity measurements for future reference, analysis, and compliance purposes. This can be done manually or using the data logging capabilities of the meter, if available. Note down any significant events or changes in the factory environment that may impact the readings.

-

Alarm Settings: Configure alarm thresholds based on the desired temperature and humidity ranges for your specific processes. Set the alarms to notify you when conditions exceed or fall below the specified limits. Ensure that alarm notifications are properly received and promptly addressed to prevent any adverse effects.

WHY DO CUSTOMERS CHOOSE VNATECH?

Quality

Vnatech commits that all of our products meet quality requirements when delivered to customers

Reputation

With more than 10 years in the field of manufacturing, installing machinery and equipment and designing systems for the factory, Vnatech is a reputable and trustworthy address.

Good service

Coming to Vnatech, you will always be warmly welcomed by the staff, given complete, accurate and quick information and positive after-sales services.

Reasonable price

Our products and components are imported directly from large, reputable manufacturers, without going through third parties, so they always have the most competitive prices.