Engineering Service

Professional industrial electrical installation process

Electrical systems play an extremely important role in industrial production activities. Industrial electrical installation that is safe, efficient, and meets technical standards is a key factor to ensure. The article below will share and help you answer what steps the industrial electrical installation process includes.

What is the industrial electrical system?

The industrial power system is a power transmission and distribution system to helps machines and equipment operate for production, business, and services. This system ensures the stable operation of the power source while developing a safe, reasonable, and effective power transmission system to serve all industrial activities.

What does an industrial electrical system include?

After understanding what an industrial electrical installation is? We need to understand what components a complete industrial electrical system includes. Understanding clearly before installing the system will help us optimize construction time.

Industrial electrical systems include many parts and each part has a different function and task. As follows:

Medium voltage system supplies power to the general transformer

This is the transformer part that converts electricity from the national power grid to serve production and business. This system aims to stabilize the current and adjust the voltage up and down to the appropriate level. Thanks to that, machinery and equipment in the factory can operate effectively.

Electrical distribution cabinet system

This is a system installed to manage the circulation of power sources in the factory to ensure the safety of industrial equipment and machinery.

Industrial equipment electrical cabinet system

This is a control cabinet system to adjust the power supply for industrial electrical equipment on and off. Electrical equipment cabinets often include an ammeter, Voltmeter, fuse, etc. to ensure the safety of machinery and equipment.

Industrial equipment system

This is the core part, directly affecting production and business. Industrial electrical equipment systems include machinery and equipment directly involved in the production process (production line systems, processing, packaging, etc.) and other electrical components (systems that use electricity). lighting, air conditioning, ventilation, etc.).

The role of industrial electrical systems

Industrial electrical systems play an important role in the production and operation of each enterprise’s products, specifically:

- Technical improvements during use, improving the productivity of industrial equipment. Ensure the staff carries out the production process continuously, without interruption.

- Save labor.

- Reduce production costs significantly, lower product prices, and improve quality.

- Bringing modern technology into a more dynamic, mechanical system helps save time.

- The price is consistent with the product manufacturing process.

- Can replace humans, doing things that humans cannot do manually.

What criteria should be kept in mind when installing industrial electricity?

Industrial electrical installation must meet the following requirements:

- Handover equipment needs to meet electrical safety criteria. Avoid losing safety during operation and use

- The system operates smoothly and efficiently. This criterion is evaluated by the system’s working capacity. It needs to ensure that it does not affect the production progress of the business

- Saving operating costs: Need to calculate the correct scale and capacity needed. Learn how to properly arrange and use equipment to avoid wasting electricity

- Meet state standards: Industrial electrical systems used need to ensure standards such as TCVN 7447-5-51: 2010, TCBN 394:2007…

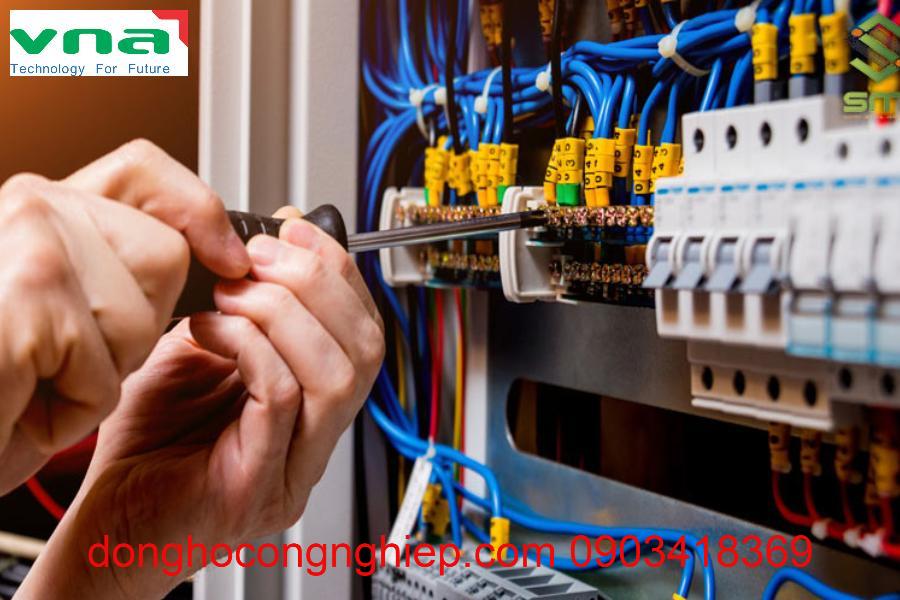

Professional industrial electrical installation process

Construction of light electrical systems and industrial electrical systems is an important stage. The construction will directly affect all future operations of the building, factory, and workshop. To ensure electrical safety, when proceeding, you need to follow the steps below:

Prepare necessary equipment for industrial electrical installation

To save construction time, the first thing you need to do is prepare the necessary equipment. Industrial electrical systems will be somewhat different from residential electrical systems. Therefore, there will be some separate equipment that is not available when installing civil electricity, such as:

- Transformer: Industrial electricity has a fairly high voltage level (380V). Therefore, it is necessary to use a transformer to ensure stable operation of the power source. It is necessary to ensure safe power transmission to machinery and equipment during installation.

- Industrial factory electrical cabinets: These are specialized large cabinets used as distribution electrical cabinets. Electrical control cabinets for mechanical systems and electrical systems.

- Electrical conductors: 1-phase and 3-phase electrical transmission wires are used to conduct electricity from outside as well as inside the factory.

- System protection equipment: Including circuit breakers, circuit breakers, relays, etc., which have the function of protecting the electrical system when overloaded or when the current is unstable, ensuring user safety.

- Signaling devices: Indicator lights, bells, etc. to warn about operating status. Especially helps to recognize warnings when the system has problems

Surveying projects, receiving customer information

After preparing all the electrical equipment needed to construct and install the electrical system. The construction unit needs to come directly to the project and location where they will perform the work. Thanks to that, the unit can measure, survey, and make accurate and appropriate calculations.

In addition, the factory electrical system construction unit also needs to pay attention to customer requirements. As well as the characteristics of the business industry. From there, we can have a suitable, effective, and economical plan for the factory’s electrical system.

Design industrial electrical installation drawings

To have a perfect, standard construction drawing, it is necessary to ensure the following criteria:

- Strictly comply with standards on language and symbols used in electrical technical drawings

- Ensure electrical safety during both construction and operation

- Commitment to the ability to meet the capacity and efficiency required by the business

- Calculate construction costs to ensure the most economical and optimal results

Construction and industrial electrical installation

Construction and industrial electrical installation are the most important in the entire process. When constructing, and implementing units need to ensure the following factors:

- Construction by approved design drawings.

- Ensure the safety of the system during operation.

- Commitment to the efficiency of the operation of the devices in the system.

- Easier to repair and maintain industrial electrical systems in the future.

Note when installing industrial electricity

As is known, electricity is a form of energy that contributes significantly to all human activities. Therefore, industrial electrical safety is always inspected and monitored regularly.

To conduct safe industrial electrical installation, the facility owner must comply with the principles and methods of safely arranging and operating the electrical network. Comply with the following safety principles:

For those in charge of expertise

It is necessary to clearly understand the equipment, electrical diagrams, and operating techniques to avoid the risk of danger. Must know about electrical safety when bad situations occur. Able to handle situations and provide first aid to people suffering from electric shock.

For workers

Ensure the principle of 1 person watching, and 1 person doing the installation.

For businesses

Must regularly review and check the entire network. Follow proper electrical safety rules.

In addition, it is necessary to choose the correct voltage as well as perform grounding. When working with electrical equipment, workers must use specialized tools and protective equipment. Make sure that insulating materials are always available and that electrical equipment is regularly inspected.

Communications

VIETNAM TECHNOLOGY DEVELOPMENT AND TRANSFER JOINT STOCK COMPANY.

Office: VT09-BT02 – Xa La Urban Area – Ha Dong – Hanoi.

Tax code: 01 05 158 192

Home page: www.vnatech.com.vn

Website: http://donghocongnghiep.com/

Email: contact@vnatech.com.vn