Engineering Service

Instructions for installing the most detailed electrical cabinet connection diagram

Electrical cabinet connections are a popular product and are widely applied in many areas of life. However, not everyone has a deep understanding of the roles and diagrams of connecting electrical cabinets safely and accurately.

In the following article, we will introduce to you six steps to connect electrical cabinets. Hopefully, this will be a useful reference to help you operate the device safely and ensure the best efficiency.

What is an electrical cabinet connection?

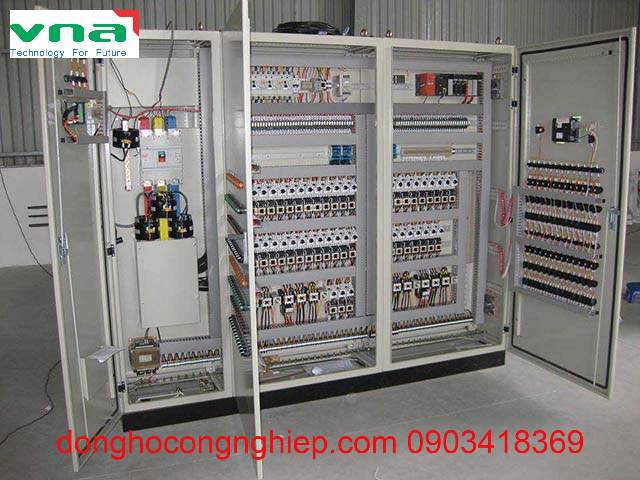

Electrical cabinet connection is the process of connecting electrical components such as switches, circuit breakers, control panels, protection circuits, and cables in the electrical cabinet to form a complete electrical system. This process includes cutting, stripping wires, splicing, and connecting electrical components according to the previously designed connection diagram. Electrical cabinet connections ensure the safe and efficient operation of the electrical system, providing a stable power source and protecting equipment from the risk of overload, short circuits, and other electrical problems.

The most detailed electrical cabinet connector diagram

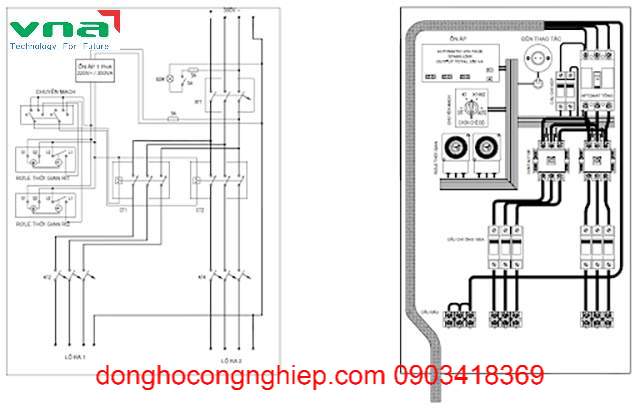

Electrical cabinet connection diagrams can have many different forms, depending on the purpose of use and structure of the specific electrical cabinet. However, below is an example of a detailed electrical cabinet connection diagram:

Main power supply:

The diagram starts with the main power supply, which can be power from the grid or from a backup power source.

Transformer:

If the electrical cabinet uses a transformer to regulate voltage, the transformer will be connected to the main power supply.

Main switch:

The main switch is the starting point of the electrical system in the cabinet. It is connected to the main power supply and is used to control the power supply to the cabinet.

Distribution circuits:

From the main switch, the distribution circuits will go to other electrical devices and loads in the electrical cabinet. These distribution circuits may include control panels, circuit breakers, circuit switches, and other protective components.

Protection devices:

In the electrical cabinet connection diagram, protection devices such as circuit breakers, protection relays, circuit switches, temperature protection, and overcurrent protection are connected to ensure safety and protection. power system.

Other devices and loads:

Finally, other electrical devices and loads such as lights, machines, and electronic devices will be connected to the distribution circuits to get power and operate.

The most detailed instructions for connecting electrical cabinets

Electrical cabinet connection is the process of connecting components and circuits in the cabinet to form a complete electrical system. Below are the most detailed electrical cabinet connection instructions:

Prepare:

Identify components and equipment that need to be connected to the electrical cabinet. Prepare connection diagrams and manufacturer’s instructions.

Install components:

Install components such as main switches, control panels, circuit breakers, protective relays, and other equipment in the correct locations as prescribed. Make sure that the components are firmly fixed and do not cause collisions or misconnections.

Prepare cables:

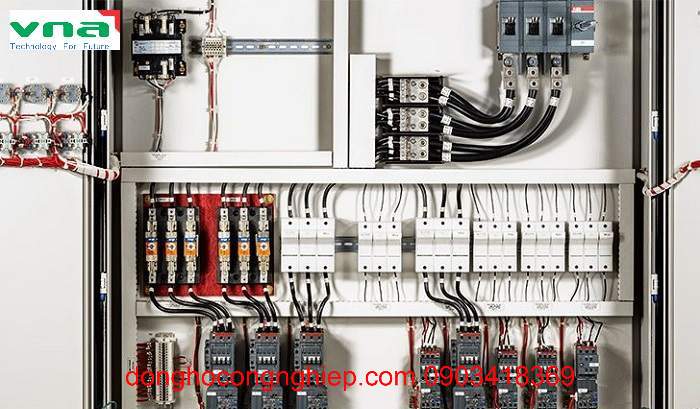

Prepare cables of appropriate length to connect components together. Peel the wire at both ends and remove the insulation for good electrical contact.

Cable connection:

Connect cables according to the specified connection diagram. Connect the cables to the correct connectors or terminals on the components and circuits. Make sure connections are trimmed, secure, and have no loose wires.

Check and confirm:

Check the connections and electrical connections to see if they are correct and secure. Use an electrical measuring device to test the circuit and ensure that there are no short circuits or errors.

Protection and packaging:

Make sure that the electrical cabinet is protected from dust, moisture, and other environmental factors. Pack the electrical cabinet securely and ensure safety during transportation and installation.

Electrical cabinet connection installation process

The electrical cabinet connection installation process is divided into 6 specific steps as follows:

Determine technical specifications to select suitable equipment

To make electrical cabinet connections, you need to calculate details to choose the most suitable devices.

With low voltage distribution cabinets:

You need to clearly establish the number of branches to distribute and the load to accurately calculate the value of devices such as relays, circuit breakers, wires, etc.

Equipment needs to balance economics and technology. To save costs, you should not choose equipment with too high value.

For electrical control cabinets:

It is necessary to clearly understand technology requirements to calculate and select appropriate feature devices.

Depending on the investor’s requirements as well as the level of design of the electrical cabinet cooking system, you can choose the most suitable equipment.

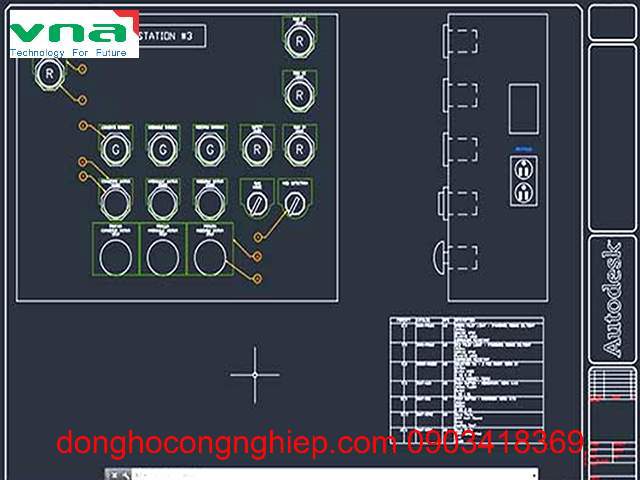

Draw equipment layout diagrams and operating principle diagrams

Designing and drawing equipment layout diagrams plays a huge role in creating industrial electrical cabinets. Therefore, when designing, it is necessary to ensure functions while optimizing costs and reducing materials. In addition, it is necessary to consider the ability to expand and change the system to make repair and maintenance simpler and more convenient.

The design process must be invested in and carefully monitored to avoid possible errors, leading to the need to redesign the entire system from scratch.

Processing and installation of cabinet covers

After completing the layout diagram, you need to determine the electrical cabinet shell. Then, the wood on the cabinet surface is processed to arrange devices such as buttons, clocks, indicator lights, etc. The electrical cabinet shell processing process is carried out using CNC machines to bring absolute precision.

In addition, the folding and finishing stages will be performed synchronously on modern technological lines. When installing devices on electrical cabinets, you need to comply with the following issues:

- Some equipment such as a current meter, power indicator light, indicator, and voltage meter must be placed at eye level so that operators can easily observe parameters.

- Control device: switches and buttons placed below, at chest level to control and operate the device more simply

- Switches and buttons need to be placed in one row to make operation more convenient

- On the cabinet shell, there must be drilled holes connected to the side such as wire connection position, ventilation fan, shielding net, etc.

Electrical wiring

When marking electrical wires, you need to pay attention to the following issues:

- Wires between devices need to be arranged neatly and reasonably

- The core heads must be color-coded and numbered for easy repair and control

- Power circuit wires and signal wires must be shielded to prevent interference

- Wire the power circuit first, then the control wire

- Power circuit wires and control wires must be arranged perpendicular to each other

Important notes when installing electrical cabinets

When installing industrial electrical cabinets, you need to pay attention to the following issues:

- The dagram needs to relate to the equipment layout in the cabinet with 3 main parts: control circuit, power circuit, automatic circuit

- Electrical cabinets are arranged in accordance with the output direction and the grid direction to ensure safety

- The mechanical part of the cabinet must be watertight to avoid affecting the equipment in the cabinet. Depending on the total of the auxiliary loads below, the automatic shutdown intensity is selected to be most suitable.

- In industrial electrical cabinets, it is necessary to arrange additional 220V power sockets for easier maintenance.

- Equipment needs to be arranged appropriately in groups to make the operation process more convenient

- Use a 300w incandescent light bulb to check the ground wire of the industrial cabinet

Communications

VIETNAM TECHNOLOGY DEVELOPMENT AND TRANSFER JOINT STOCK COMPANY.

Office: VT09-BT02 – Xa La Urban Area – Ha Dong – Hanoi.

Tax code: 01 05 158 192

Home page: www.vnatech.com.vn

Website: http://donghocongnghiep.com/

Email: contact@vnatech.com.vn

Hotline: 0903 418 369 / 0977 550 85

Tel: 024 668 3 261 / 098 311 7863