Engineering Service

Installation of industrial machinery lines

Installation of industrial machinery lines, industrial machinery, and equipment lines play an important role in the production process of businesses. To ensure product performance and quality, the installation of industrial machinery and equipment lines is extremely important.

What are the advantages of industrial machinery line installation service?

Installation of industrial machinery lines brings many important advantages to businesses.

Increase productivity and performance

Installing professional industrial machinery lines helps optimize production processes and increase working efficiency. The production line system is designed appropriately and optimizes production stages, helping to minimize waiting time, increase production speed, and improve productivity.

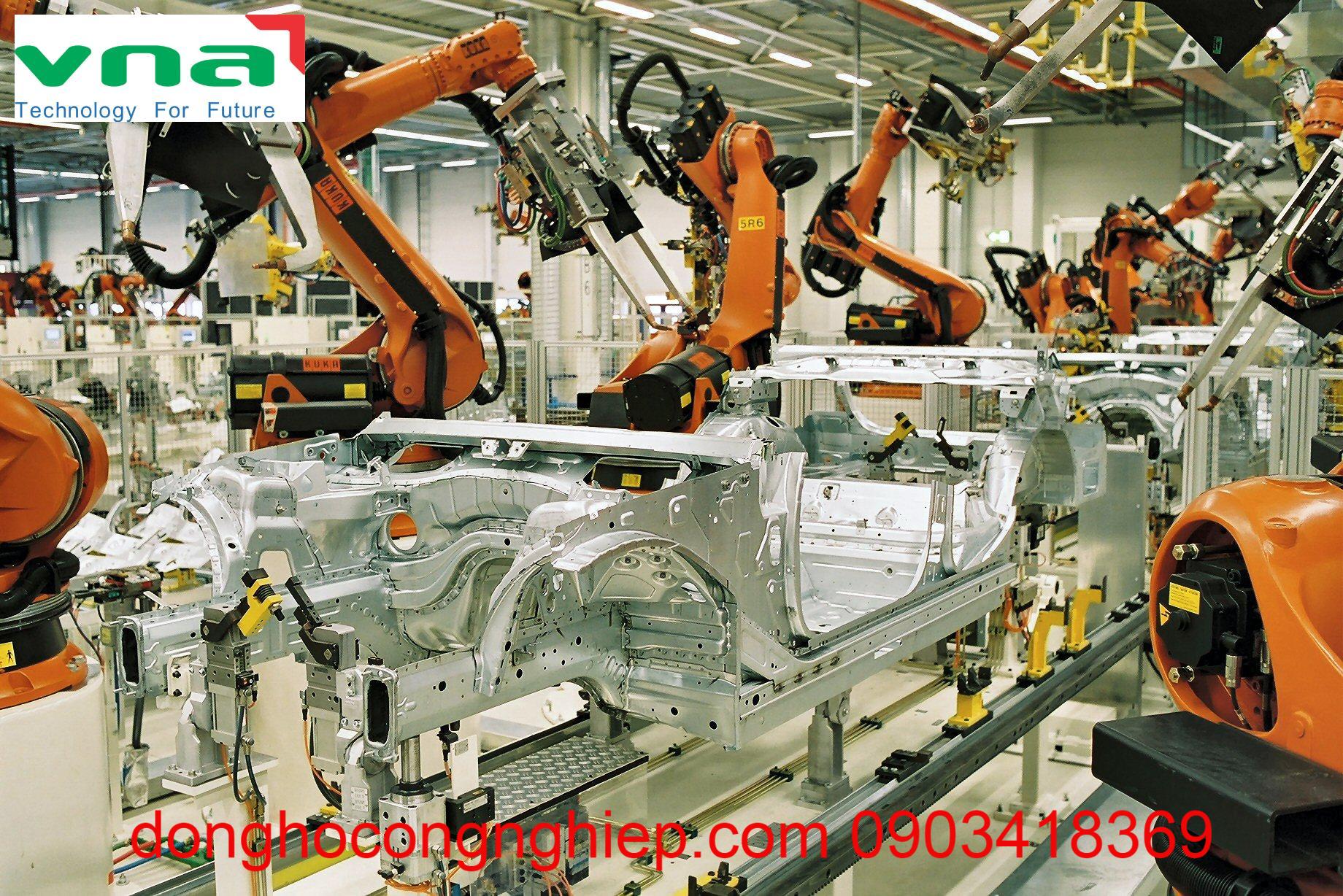

Installation of industrial machinery lines increases productivity and performance

Ensuring quality and accuracy with installation of industrial machinery lines

Installation of industrial machinery lines are installed accurately and according to technical procedures, ensuring product quality and accuracy. The production process is tightly controlled and automated, minimizing human errors and ensuring consistency in the final product.

Save costs and increase competitiveness

An efficient industrial machinery line helps save production and operating costs. Process automation and optimization help reduce waste and increase material usage efficiency. In addition, improving productivity and product quality can also help increase competition in the market.

Reliability and easy maintenance

Installation of industrial machinery lines are installed accurately and use reliable equipment and technology. This helps ensure stable and trouble-free operation, minimizing machine downtime and disruptions in the production process. Maintenance and repair are also easier because the system is designed and installed systematically and conveniently.

Compliance with regulations and standards

Installation of industrial machinery line services ensures compliance with safety and technical regulations and standards. This ensures that the system operates in a secure environment and complies with legal requirements.

How much does it cost for industrial machinery line installation services?

The cost of installation of industrial machinery lines is very diverse and depends on many different factors. These factors may include:

Type of device:

The cost of installing complex equipment such as automobile manufacturing machinery or electronics manufacturing machinery will be higher than that of simple equipment such as food production machinery.

Factory size:

Larger factories will require more equipment and therefore higher installation costs.

Job complexity:

If the installation job requires a lot of advanced techniques and takes a long time to complete, the cost will also increase.

Completion time:

If you want the installation service to be completed in a short time, you will have to pay additional costs for overtime and faster work.

Location:

Installation costs in urban areas will be higher than in rural areas.

Above are the factors that affect the cost of industrial machinery and equipment installation services. However, to get accurate prices, you should contact the service providers directly for detailed advice and quotes.

Things to keep in mind when installation of industrial machinery lines

Installing of industrial machinery lines, there are a few important things to keep in mind to ensure the process takes place efficiently and safely. Here are the things to keep in mind:

Machine selection and standards:

Choose machines that suit your needs and production requirements. Determine required technical, quality, and performance standards for the line and ensure selected equipment complies with these standards.

Design and layout:

Installation of industrial machinery lines design must be carefully considered to ensure smoothness and efficiency in the production process. The arrangement of machines, equipment, and connection nodes must be determined to facilitate operation, maintenance, and repair.

Labor safety:

Ensure that machinery lines are designed and installed in compliance with labor safety regulations. This includes providing protective measures, ensuring employee safety, and providing occupational safety training to those involved in line operations.

Quality control:

Establish a quality control system to ensure that machinery and production processes comply with quality standards. Regular inspection and quality control from installation to operation are necessary.

Maintenance and upkeep:

Ensure that routine maintenance and servicing plans are established and followed. This helps maintain the normal operation of the line and prolongs the life of the machinery. At the same time, train employees on basic maintenance to be able to handle small and simple jobs.

Training and support:

Ensure that employees are trained in the use and operation of newly installed machinery. Provide user manuals, documentation, and technical support to help employees work efficiently and solve technical problems properly.

System integration:

When installing industrial machinery lines, ensure good integration between different elements in the production process. This ensures a coherent and effective connection between machines and equipment.

Final inspection and testing:

Before putting the line into operation, perform final inspection and testing to ensure that every equipment and system operates properly and complies with technical standards and quality. This helps ensure that the machinery line will operate stably and effectively when put into production.

How long does it take to install industrial machinery lines? How to choose a reputable service?

How long does it take to install industrial machinery and equipment lines?

Installation of industrial machinery lines depends on many different factors such as size, complexity, quantity, and technical characteristics of each device. However, during the installation process, engineers and technicians will carry out steps to prepare, assemble, test, and adjust the equipment to ensure stable and effective operation.

Installation time

Installation time can last from a few days to several months depending on the scale of the project. In addition, preparing the working environment and accessories is also an important factor to ensure the installation progress is carried out quickly and accurately.

Therefore, to ensure progress and quality of installation, there needs to be close cooperation between relevant parties during project implementation. In addition, the use of advanced technology and the practical experience of experts also help optimize installation time and improve the production efficiency of the business.

How to choose a reputable service?

Reputable service is an important factor in the process of choosing and using services. Therefore, to ensure that you will receive the best service possible, consider and take the following steps to choose a reputable service.

Step 1: Learn about the service provider

Before deciding to use a company’s services, you need to learn about that company. You can look for information on the company’s website or search on service review sites. Important information you should learn includes:

– Company contact information.

– Field of operation of the company.

– Information about the products or services that the company provides.

– Information about the company’s experience and certifications.

– Reviews from previous customers.

Step 2: Check the company’s certificates and licenses

Checking a company’s certifications and licenses is an important step in ensuring that the company is qualified and authorized to operate in the field in which it provides services. You can check the company’s certificates and licenses on the website of the authorities or ask the company to provide them to you.

Step 3: Learn about service quality

To evaluate the quality of a company’s service, you can search for information from previous customers or read reviews on service review websites. You can also ask the company to provide you with a list of customers who have used their services so you can contact them and learn more.

Step 4: Compare prices

Comparing prices between service providers is an important step in ensuring that you are not being ripped off during the service process. However, you should not just choose the company with the cheapest price without paying attention to the quality of service.

Step 5: Contact and request more information

Finally, after you have researched and compared information from service providers, you should contact and request more information from the companies you are interested in. You can request detailed quotes or ask more about the company’s policies and conditions for using the company’s services.

Industrial machinery and equipment installation service at Vnatech

Vnatech is a unit specializing in providing top-quality and prestigious industrial machinery and equipment installation services in Vietnam. With a team of experienced and highly skilled engineers, we are committed to providing customers with the most optimal solutions for their production systems.

We provide services from consulting, design, manufacturing, installation, and maintenance of industrial machinery and equipment lines. With product and service quality as the top priority, we are always ready to support customers in every aspect.

Communications

VIETNAM TECHNOLOGY DEVELOPMENT AND TRANSFER JOINT STOCK COMPANY.

Office: VT09-BT02 – Xa La Urban Area – Ha Dong – Hanoi.

Tax code: 01 05 158 192

Home page: www.vnatech.com.vn

Website: http://donghocongnghiep.com/

Email: contact@vnatech.com.vn

Hotline: 0903 418 369 / 0977 550 85

Tel: 024 668 3 261 / 098 311 7863