Engineering Service

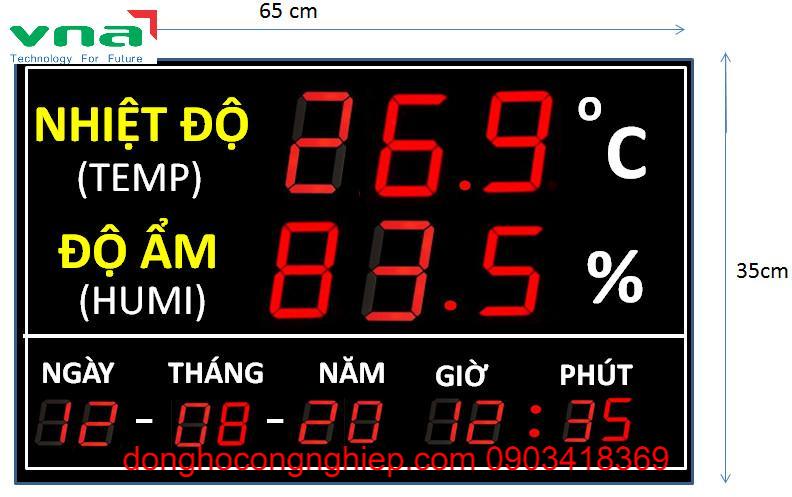

Factory temperature and humidity clock

In a factory environment, measuring temperature and humidity is critical to ensuring efficient production operations. Factory temperature and humidity clock are indispensable devices for monitoring and controlling environmental conditions. With the development of technology, temperature and humidity meters with LED screens have become a popular choice for modern factories. In this article, we will learn about the uses and benefits of factory temperature and humidity meters and why they are a reliable solution for industrial environments.

The importance of factory temperature and humidity clock

Factory temperature and humidity clock are tools to help monitor and adjust the working environment in the factory. They measure and provide information about current temperature and humidity, helping managers and employees control the factory environment accurately and promptly.

Factory temperature and humidity clock

- Temperature measurement: The factory temperature gauge allows accurate monitoring of temperature in the workspace. This is important to ensure that the work environment meets technical and safety requirements. Incorrect temperatures can affect product quality, machine performance, and employee health. Factory temperature gauge with LED display provides high brightness and easy reading, making temperature monitoring convenient and accurate.

- Humidity measurement: Factory humidity meter helps monitor humidity levels in the air. Humidity levels that are too high or too low can cause production problems. Excessive humidity can lead to the growth of bacteria and mold and affect product quality. Conversely, humidity that is too low can cause dry skin, and eye irritation and harm sensitive materials. Factory humidity meter with LED display allows monitoring of humidity levels accurately and quickly.

Benefits of using factory temperature and humidity meters

Using a temperature and humidity clock in the factory brings many important benefits, including:

Control the working environment:

Temperature and humidity meters help you monitor and control the working environment in the factory. Temperatures and humidity that are too high or too low can affect employee health and performance. By monitoring these indicators, you can adjust your air conditioning or ventilation system to create a comfortable and safe working environment.

Storage of goods:

Temperature and humidity can affect the quality and preservation of goods in the factory. If the environment is too humid, it can cause spoilage, growth of bacteria, mold, and affect sensitive goods such as electronic products, food or pharmaceuticals. Temperature and humidity gauges help you monitor this and take preventative measures or adjust the environment to better preserve your goods.

Minimize risks:

A working environment with incorrect temperature and humidity can create potential risks. For example, if the temperature is too high, it may cause a fire hazard or damage sensitive electronic devices. If humidity is too low, it can create static electricity and harm electronic devices or dry out the skin and respiratory tract, causing discomfort for employees. Using a temperature and humidity meter helps you detect these problems early and take preventative measures to minimize the risk.

Increase performance and save energy:

By monitoring temperature and humidity, you can adjust your air conditioning system or adjust ventilation to optimize performance and save energy. For example, if you notice the temperature is too high, you can adjust the cooling system to save energy while still ensuring a comfortable working environment.

Choose a suitable factory temperature and humidity clock

Type of meter:

There are many types of temperature and humidity clock such as traditional analog meters, digital meters, touch meters, or digital meters. Consider the type of watch that suits your needs and priorities.

Size and design:

The clock needs to have a size and design suitable for the space and working environment in the factory. This includes snug fit, easy installation, and durability in harsh environments.

Interface and ease of use:

The meter should have a clear and easy-to-read interface so that users can easily read and understand temperature and humidity information. Adjustment and setting buttons should also be designed for easy and convenient use.

Connectivity and integration:

If you want to integrate a temperature and humidity meter into your factory’s automated monitoring system, make sure the meter has the ability to connect and integrate with devices and related protocols.

Performance in harsh environments:

Factory environments may include factors such as dust, grease, vibration, or high temperatures. Choose a watch that is dustproof, waterproof, anti-vibration, and capable of stable operation in this harsh environment.

Reliability and technical support:

Temperature and humidity meters need to be highly reliable and have technical support from the manufacturer. Learn about product reliability and technical support, warranty, and after-sales service.

Practical application of factory temperature and humidity meter

Production environment management:

Factory temperature and humidity meters are used to monitor and adjust the working environment in the factory. These parameters provide important data to ensure temperature and humidity are at ideal levels for production. This helps ensure product quality, increase productivity, and minimize the risk of damage to environmentally sensitive products.

Quality control:

Factory temperature and humidity meters provide information about the working environment, helping to evaluate and control product quality. If temperature or humidity exceeds allowable thresholds, managers can take measures to adjust and stabilize the environment to ensure the product meets quality requirements.

Storage of goods:

In industries such as the food and pharmaceutical industries, factory temperature and humidity meters are used to control and monitor the storage conditions of goods. This ensures that products are stored in the right environment to prevent damage, and loss and ensure consumer safety.

Regulatory compliance:

In some industries, factory temperature and humidity clock are used to comply with regulations and standards related to the work environment. Parameters are recorded and reported to ensure that the environment meets safety, quality, and regulatory compliance requirements.

Communications

VIETNAM TECHNOLOGY DEVELOPMENT AND TRANSFER JOINT STOCK COMPANY.

Office: VT09-BT02 – Xa La Urban Area – Ha Dong – Hanoi.

Tax code: 01 05 158 192

Home page: www.vnatech.com.vn

Website: http://donghocongnghiep.com/

Email: contact@vnatech.com.vn